Optical fiber splicing is a technique used to permanently connect two optical fibers together. For optical fiber communication this method is used to increase the length of the fiber optic cable for better together with long distance optical signal transmission. Splicing is also used when a buried cable is mistakenly cut to reconnect the fiber optic cables. There are two types of splicing methods which are:

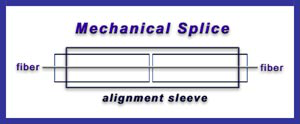

- Mechanical Splicing

Mechanical fiber splices are simply configuration, designed to hold the two fiber ends in an accurately aligned position allowing light to pass from one fiber to the other. Typical loss – 0.3dB.

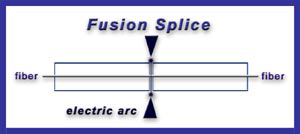

- Fusion Splicing

In fusion fiber splicing a machine is used to align the two fiber ends precisely, then the ends of the glass are “fused” or “welded” together using some type of heat or electric arc. This creates a continuous relation between the fibers allowing transmission of very low loss light. Typical loss – 0.1dB.

In Malaysia, economics is the usual explanation for preferring one process over another. Mechanical optical fiber splicing has a low initial investment but is costing more per splicing. Although the cost per splice for fusion optical fiber splicing is lower, the initial expenditure is considerably higher depending on the performance and functionality of the purchased fusion splicing system. The more accurate the alignment needed (better alignment results in lower loss, the more expensive machine should be used.

As for the output of each splicing process, the decision is always based on the industry. Fusion splicing results in lower loss and less reflection of the back than mechanical splicing, as the resulting splicing points are almost seamless. Fusion splices are primarily used for single-mode fiber where Mechanical splices operate for single- and multi-mode fiber.

Read more: GPON Technology Malaysia